Automation and Measuring Stations

SPC-Measuring Stations

STOTZ SPC measurement stations are configured according to customer requirements and are used when multiple measurement tasks from handheld measuring instruments and/or measuring devices are combined at one measurement station, if 100% testing is not necessary.

Through successful sampling inspection at your measurement station, the improvement and optimization of the ongoing production process is ensured and documented with our STOTZ measurement computers.

Our SPC measurement stations are designed according to common industry standards and consist of robust aluminum profiles and sufficient storage space for your measuring instruments.

The STOTZ SPC-M software also guides new and inexperienced users through the necessary measurement processes. With the help of the SPC measurement computers, process monitoring can be carried out directly at the inspection station, or the data can be transmitted via the network and processed further with corresponding CAQ systems. Integration with common evaluation systems such as qs-STAT is easily possible.

Our measurement stations are characterized by high quality, ergonomics, and durability. You benefit from our expertise gained from several decades of innovative development.

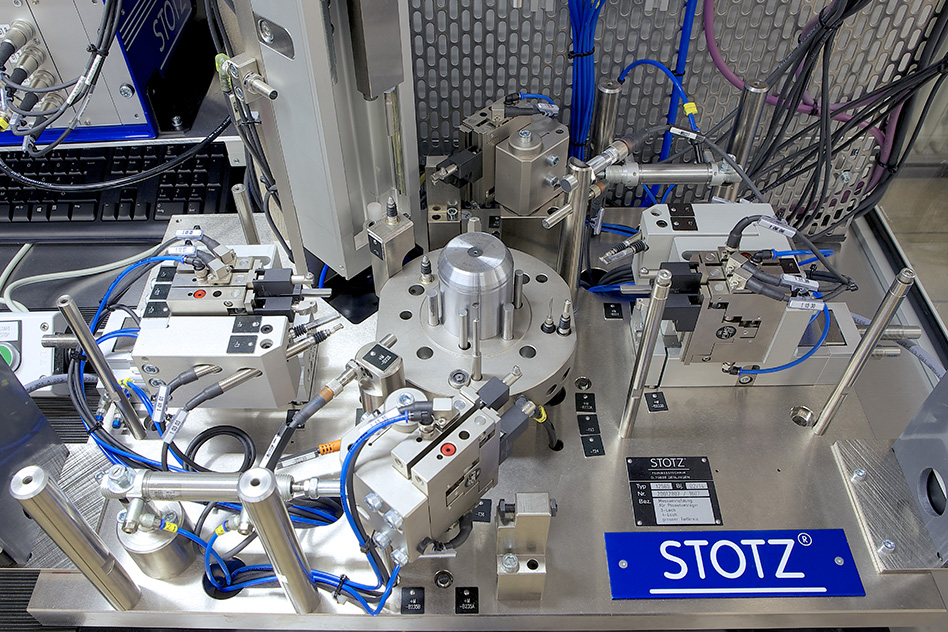

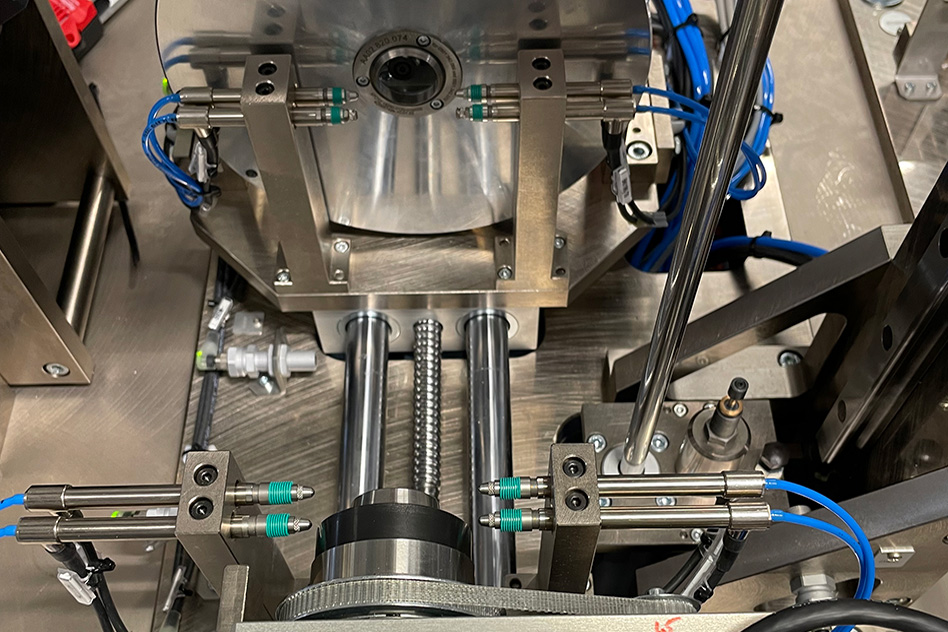

Scanning measuring Stations

STOTZ scanning measuring stations are used for the fully automatic 100% inspection of high-precision diameters (bores and cylinders) in several, freely selectable measuring planes.

Our products are characterized by their high quality, short cycle times and durability.

Depending on the task, we measure your diameters statically or dynamically.

Through successful 100% testing, we control and optimize your production process.

Our measuring stations are designed according to the most common industry standards and consist of robust aluminum profiles, sufficient storage space for your setting masters and the latest electronic components from renowned manufacturers.

Our STOTZ SPC-M software documents your measurement results, is used for process monitoring and controls system processes.

Your measured values are transmitted to machining centers, robots or gantries via Profinet, Profibus, Ethernet or hardware interface.

Furthermore, data can also be forwarded to the network and further processed with corresponding CAQ systems.

Connection to common evaluation systems such as qs-STAT is therefore possible without any problems.

Measuring tasks:

- Inner diameter

- Outer diameter

- Straightness

- Parallelism

- Roundness

- Cylinder shape

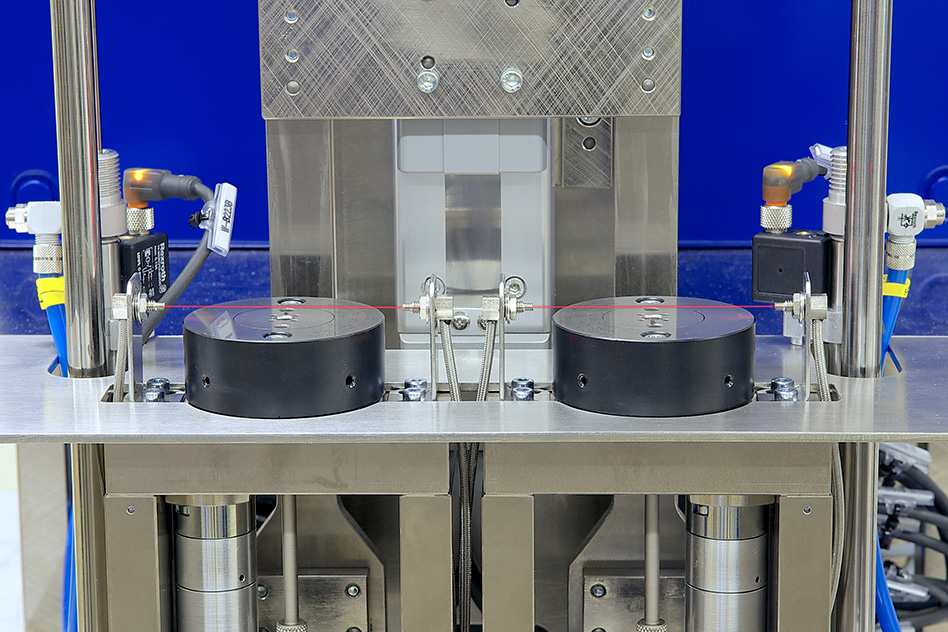

Post Process shaft Measuring Station

STOTZ post process shaft measuring stations are mainly used for the fully automatic 100% inspection of diameters, cylinder shapes and concentricity on shafts.

Our products are characterized by high quality, short cycle times and a long service life.

We control and optimize your production process through successful 100% testing.

Our measuring stations are designed according to the most common industry standards and consist of robust aluminum profiles, sufficient storage space for your setting masters and the latest electronic components from renowned manufacturers.

Our STOTZ SPC-M software documents your measurement results, is used for process monitoring and controls system processes.

Your measured values are transmitted to machining centers, robots or gantries via Profinet, Profibus, Ethernet or hardware interface.

Furthermore, data can also be forwarded to the network and further processed with corresponding CAQ systems.

Connection to common evaluation systems such as qs-STAT is therefore possible without any problems.

Measuring tasks:

- Outer diameter

- Cylinder shapes

- Run-outs

- axial run-outs

- Inside diameter

- Concentricity

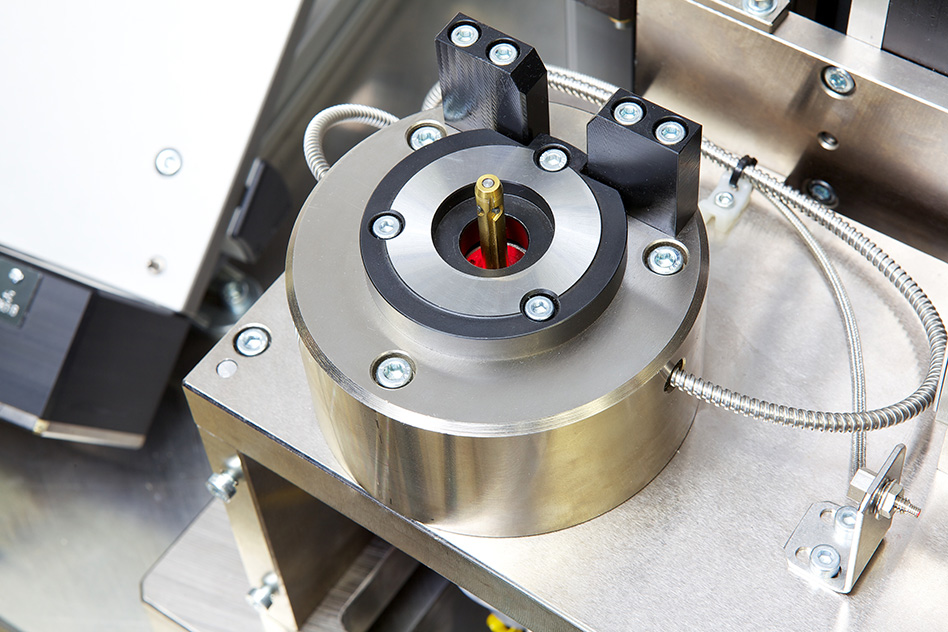

Post Process gear measuring stations

STOTZ post process gear measuring stations are used for the fully automatic 100% inspection of diameters, heights and concentricity on gears.

Our products are characterized by high quality, short cycle times and a long service life.

We control and optimize your production process through successful 100% testing.

Depending on the task, we measure your diameters, heights and runs.

Our measuring stations are designed according to the most common industry standards and consist of robust aluminum profiles, sufficient storage space for your setting masters and the latest electronic components from renowned manufacturers.

Our STOTZ SPC-M software documents your measurement results, is used for process monitoring and controls system processes.

Your measured values are transmitted to machining centers, robots or gantries via Profinet, Profibus, Ethernet or hardware interface.

Furthermore, data can also be forwarded to the network and further processed with corresponding CAQ systems.

Connection to common evaluation systems such as qs-STAT is therefore possible without any problems.

Measuring tasks:

- Inner diameter

- Outer diameter

- heights

- concentric runs

- axial run-outs

- Cylinder shapes

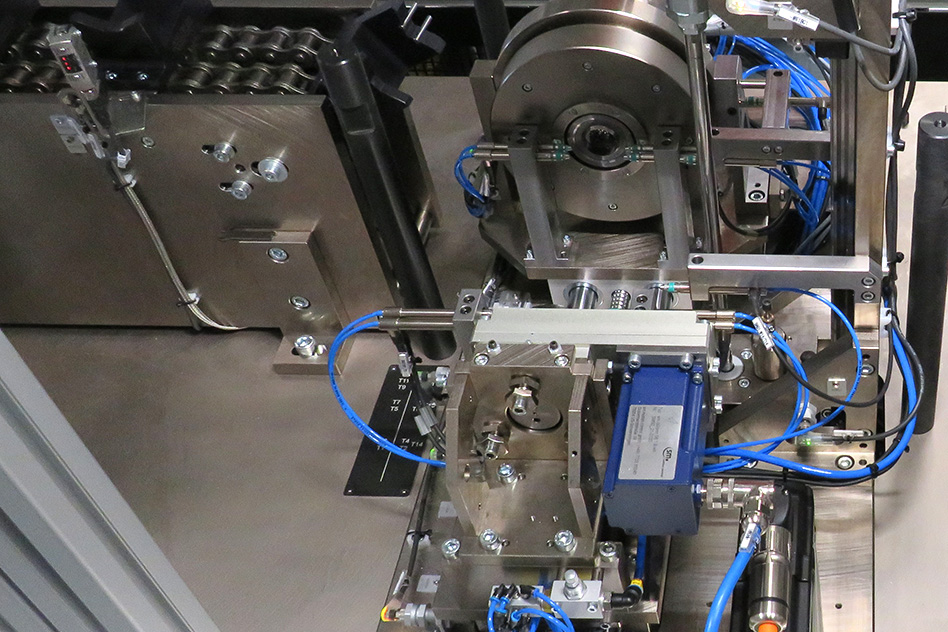

Post Process housing measuring stations

STOTZ post process housing measuring stations are used for the fully automatic 100% inspection of diameters, heights and lengths of housings.

Our products are characterized by high quality, short cycle times and a long service life.

We control and optimize your production process through successful 100% testing.

Our measuring stations are designed according to the most common industry standards and consist of robust aluminum profiles, sufficient storage space for your setting masters and the latest electronic components from well-known manufacturers.

Our STOTZ SPC-M software documents your measurement results, is used for process monitoring and controls system processes.

Your measured values are transmitted to machining centers, robots or gantries via Profinet, Profibus, Ethernet or hardware interface.

Furthermore, data can also be forwarded to the network and further processed with corresponding CAQ systems.

Connection to common evaluation systems such as qs-STAT is therefore possible without any problems.

Measuring tasks:

- Diameter

- heights

- lengths

- flatnesses

- parallelisms

Clamping shoulder measuring devices

Measurement automation and measurement systems