Measuring Computer / Software

MSM

The pneumatic electronic measuring column MSM was designed as a compact and cost-effective solution for manual measuring tasks. All settings, including program selection, are made using a touchscreen color display.

The MSM offers optional interfaces (e.g. RS232, USB, Profibus, Ethernet) for further processing of measurement values or data storage (saving measurement values in .txt or Stotz standard .dfq format).

The device can be modularly expanded from one pneumatic measuring channel (Type: K, M1, P, X) to up to four pneumatic measuring channels of different types. In addition to these pneumatic channels, two optional inductive inputs can also be used in parallel.

- Pneumatic and tactile length measurements

- Compact design

- Touchscreen color display

- Easy operation

- Maximum measurement stability and minimal air consumption through monitoring of air supply

- Stotz standard measurement software SPC-M

- Simple statistical analysis

- Data exchange between MSM devices and higher-level networks with software for central quality considerations

MRA

The measurement computer MRA is designed as a touchscreen panel computer with decentralized data acquisition.

The external I/O and measurement modules can be connected via Rs232, USB, or Ethernet.

The digital plug-in system DES is used for data acquisition. With a DES, the user has up to 16/32 expandable measurement channels (pneumatic, inductive, analog inputs, or in combination) available.

MRA SOPHRON

The pneumatically electronic measuring and control device Sophron is the further development of the MRA Compact. The measurement computer and insertion unit are separated, each in a sturdy housing.

The components are detachable. With more interfaces than the MRA, the Sophron is more flexible and can be used in a wide range of applications.

The program selection can be done either via a worker keyboard or directly through the touchscreen. All settings are editable on the color display.

MSG-CL

The pneumatically electronic measuring and control device MSG-CL is the further development of the MSG-64L. With the MSG-CL, four inductive inputs can be used on the back of the device, and 8 pneumatic channels or 8 inductive inputs can be used on the front of the device. In addition, multiple Stotz-ITB-16 boxes can be connected to the MSG-CL to operate 16 inductive sensors each.

The base version already includes a variety of interfaces with the corresponding standard protocols (LAN, Dig. I/O 8/8 opto, RS232, USB). Expansion interfaces include a Profibus interface (slave), a Dig. I/O 16 opto, and a second LAN interface. Program selection can be done either via a worker keyboard or directly through the touchscreen.

All settings are editable on this color display. Programs can be copied, adjusted, and saved using the MSM/MRA editor available in the base version. Statistical functions, as well as a remote maintenance module, can be additionally activated.

MRA TOUCH

The MR-Touch, with its protection class of IP 65, is ideal for use in industrial production. The 17-inch touchscreen color display is integrated in a robust stainless steel housing. Intelligent peripheral modules are connected to the computers via the network, allowing for the use of additional sensors and actuators.

SPC-M Software

The measurement computers run on Windows XP and can be programmed for measurement programs using the special programming tool SPC Program Designer.

The software for the SPC-M application is available in 3 levels: SPC-M Lite as a basic version, SPC-M-S as a standard version, and SPC-M-Advanced as a version with all features. The functionality is extensive and supported by measurement libraries.

A graphic editor allows for creating comprehensive display formats and assigning corresponding data. This makes it possible, for example, to annotate photos of workpieces with the corresponding target/actual dimensions and display them online.

Depending on the requirements, the data can be stored on a USB stick, hard drive, or network. The data storage can be configured for statistical functions in the appropriate formats.

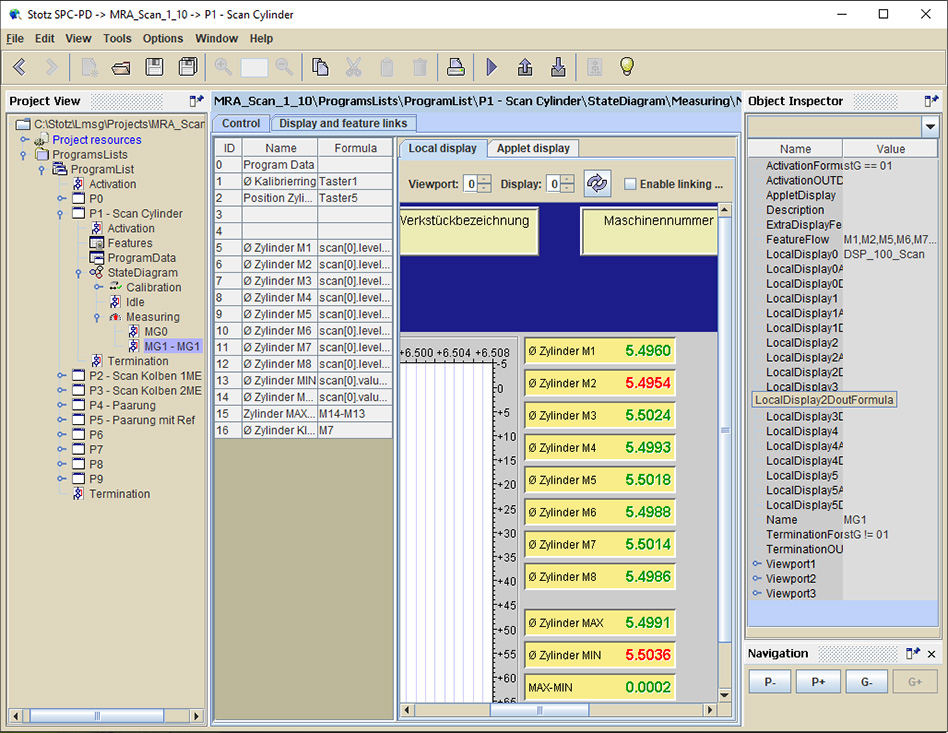

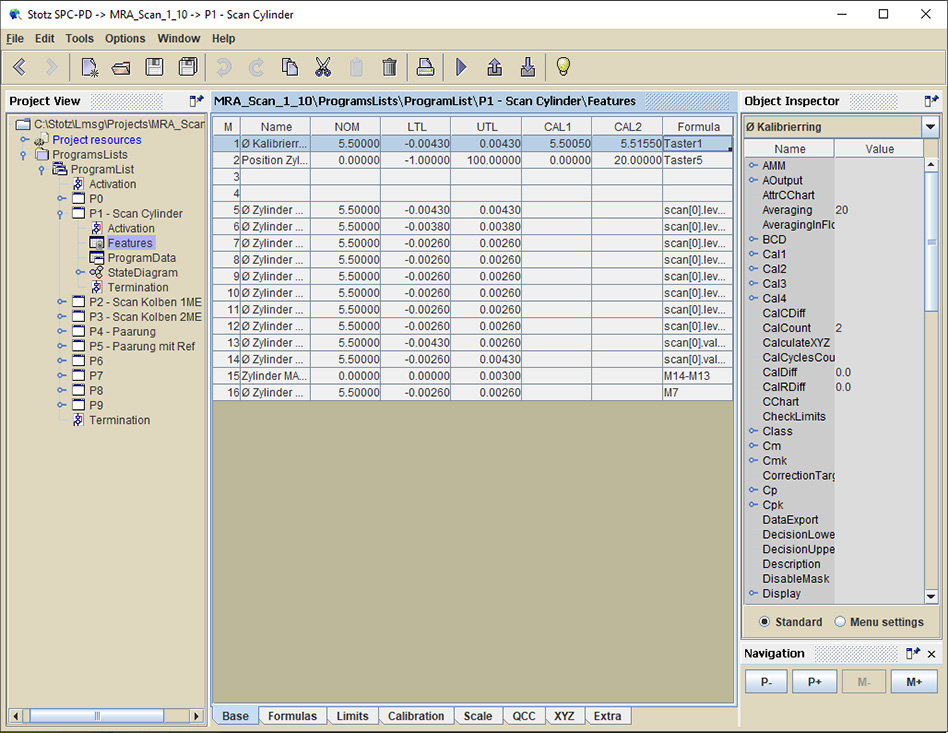

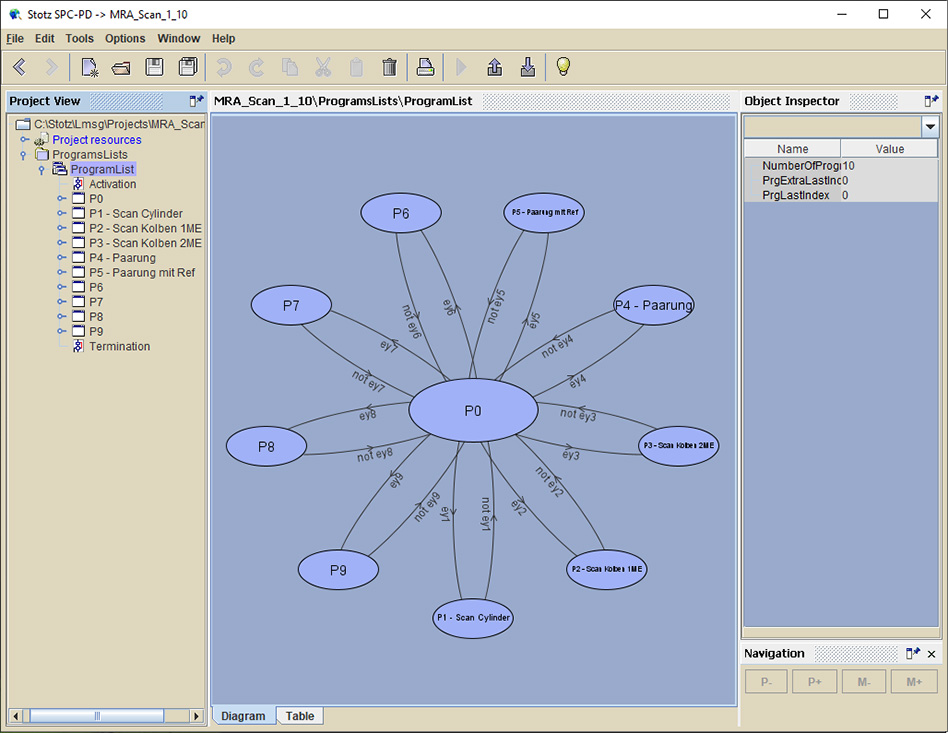

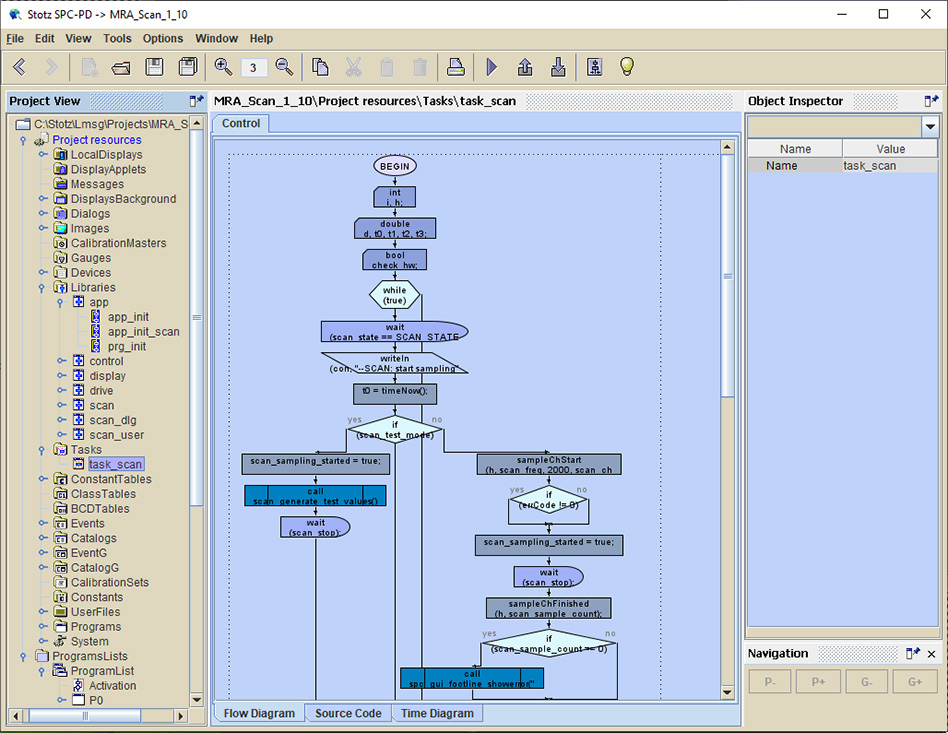

SPC-PD program designer

The software concept ensures the appropriate solution for every application. Special applications with various displays can be programmed through the program designer (PD) for specific needs.

Since the possibilities are extensive, we offer a multi-day training for this purpose. Alternatively, we can create the solution for you through our application team.

A display with an integrated workpiece image, if necessary with a sequential inspection process and corresponding feature representations, is possible.